Introduction

Understanding the term 57.2×2 can be essential in various contexts, whether it pertains to mathematics, engineering, or industrial applications. This guide provides an in-depth look at what 57.2×2 means, its practical applications, and how it is used across different industries. Whether you’re looking for mathematical explanations or engineering insights, this article will cover it all in a detailed and easy-to-understand manner.

Mathematical Interpretation of 57.2×2

Basic Arithmetic Operation

In mathematics, 57.2×2 refers to a simple multiplication operation:

57.2×2=114.457.2 \times 2 = 114.4

This calculation is straightforward and frequently used in different fields, such as finance, construction, and data analysis, where values must be doubled accurately.

Squaring 57.2

Another common mathematical interpretation could involve squaring the number:

57.22=3272.6457.2^2 = 3272.64

Squaring is commonly used in statistical calculations, engineering computations, and physics.

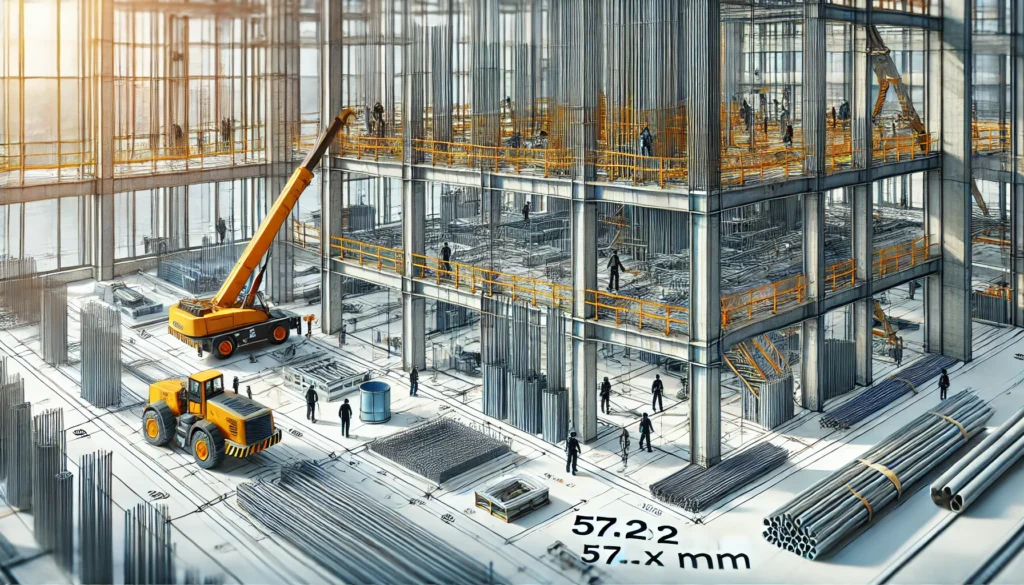

Engineering and Industrial Applications of 57.2×2

Standard Measurements

In engineering and industrial settings, 57.2 mm is a commonly used dimension for pipes, tubes, and mechanical components. Doubling this dimension (57.2×2) results in larger structural parts, which are often employed in construction and manufacturing.

Case Studies

Several industries utilize 57.2×2 mm components, including:

- Automotive Industry: Exhaust pipes and connectors.

- Construction: Structural support rods.

- Plumbing: Pipe fittings and couplings.

These applications require precise measurements to ensure compatibility and durability.

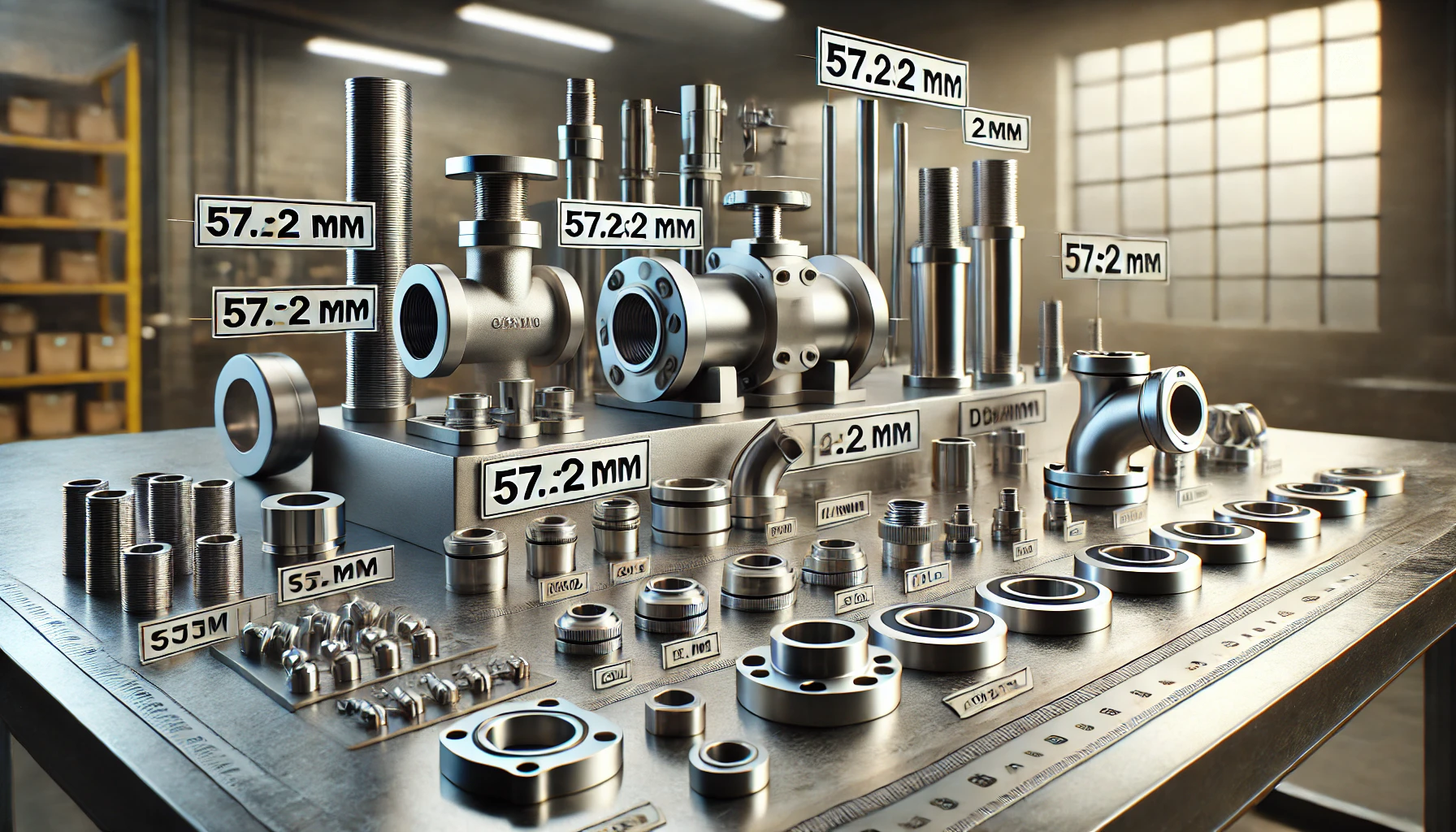

Material Specifications

Common Materials Used

Components with a 57.2 mm or 57.2×2 mm dimension are manufactured using various materials, including:

| Material Type | Characteristics | Common Usage |

|---|---|---|

| Stainless Steel | Corrosion-resistant | Pipes, fittings |

| Rubber | Flexible, durable | O-rings, gaskets |

| PVC | Lightweight, affordable | Plumbing, industrial use |

Properties and Standards

The properties of these materials, such as tensile strength, durability, and heat resistance, are crucial for industrial applications. Industry standards, such as ISO and ASTM, often govern the manufacturing of 57.2×2 mm components to ensure consistency and safety.

Design and Structural Considerations

Engineering Design Aspects

Designing components with a 57.2×2 specification requires attention to:

- Load-bearing capacity.

- Dimensional accuracy.

- Thermal expansion considerations.

Manufacturing Techniques

Manufacturing processes such as casting, extrusion, and machining are commonly used to produce parts with 57.2 mm dimensions, ensuring precision and structural integrity.

Conversion and Compatibility

Unit Conversions

For global applications, converting 57.2 mm to inches is crucial:

57.2 mm=2.25 inches57.2 \text{ mm} = 2.25 \text{ inches}

Conversion tables and online calculators are useful tools to ensure accurate conversions for international standards.

Compatibility with Other Standards

Ensuring compatibility between 57.2 mm components and existing standards helps avoid installation issues and ensures proper fitment in machinery and structures.

Frequently Asked Questions (FAQs)

- What is the result of 57.2×2 in decimal format?

- The result is 114.4.

- How does 57.2 mm compare to inches?

- 57.2 mm equals approximately 2.25 inches.

- What industries commonly use 57.2×2 measurements?

- Industries such as automotive, construction, and plumbing.

- Is 57.2×2 a standard measurement in engineering?

- Yes, it is commonly used in various applications.

- What materials are best suited for 57.2×2 components?

- Stainless steel, rubber, and PVC.

Additional FAQs to Provide More Value

- How to accurately measure 57.2 mm without professional tools?

- What are the advantages of using 57.2×2 dimensions in manufacturing?

- Are there any tolerance levels for 57.2×2 components?

- Can 57.2×2 measurements be customized for specific needs?

- What are the common challenges faced with 57.2×2 components?

Conclusion

In this comprehensive guide, we’ve explored the meaning and applications of 57.2×2, covering its mathematical significance, industrial uses, and material specifications. Understanding the proper usage and conversions of 57.2 mm dimensions can enhance efficiency in engineering, manufacturing, and everyday applications. Whether you’re dealing with construction components or mathematical calculations, having precise knowledge of 57.2×2 ensures better decision-making and optimal performance.

Other Articles

Comprehensive Guide to iloveloveloveebay.com: Gaming, Gadgets, and Tech Enthusiasts’ Paradise

Leave a Reply